SaskPower’s Boundary Dam Unit 3 (BD3) CCS facility was the first fully integrated CCS facility on a coal-fired power plant in the world, and we continue to track its performance and identify learnings that are being applied to new large-scale CCS projects across the globe.

At the end of 2022, BD3 reached an important milestone, surpassing five million tonnes of CO2 captured – equivalent to taking more than one million cars off the road for a year. The last year has also been one of significant progress, capturing an unprecedented 857,178 tonnes of CO2 during fiscal year 2022-23.

More than eight years of operation have shown BD3 to be a story of continuous improvement and has proven the value of a first-generation CCS facility. Throughout its operating life, the $900-million CCS facility has captured an average of 89 per cent of the emissions in the partial flue gas stream it has received from Unit 3 of the Boundary Dam coal-fired power station, while the capture rate exceeded 90 per cent in 2021 (94 per cent) and 2022 (91 per cent). From an engineering perspective, this is excellent performance for a first-of-a-kind facility that demonstrates the real-world application of CCS to provide substantial greenhouse gas reductions in the power generation and other industrial sectors.

Although the BD3 CCS facility has nameplate capacity to capture 90 per cent of the CO2 from all the flue gas generated by the Unit 3 turbine (an estimated 1 million tonnes of CO2 per year), the CCS facility has operated at an average of 60-65 per cent of its design capacity over the last eight years, which equates to roughly 50 per cent of all CO2 emissions generated by BD3. To date, the operation of BD3 has been focused on providing power rather than optimizing emission reductions. As a result, BD3 has operated even when CCS has been unavailable due to planned maintenance or reliability issues.

Most of the captured CO2 is transported by pipeline to an off-taker at the Weyburn oil field about 50 kilometres away, where it is injected into underground reservoirs to maximize the removal of oil before being stored permanently and safely underground – a process known as enhanced oil recovery (EOR). Recycling CO2 by selling it to an off-taker for EOR generates revenue for SaskPower that helps to offset the cost of operating the CCS facility.

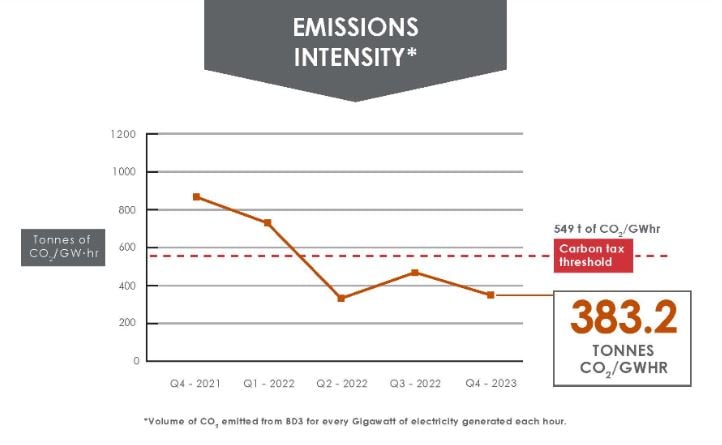

In addition to various technological challenges that come with being a first-of-a-kind facility, the reality is that for the first four years of operation, there was no financial incentive for capturing emissions beyond what was needed for EOR. This started to change with the introduction of a national price on carbon emissions that began at $20/tonne in 2019, increased to $65/tonne this year and is set to reach $170/tonnes by 2030. With recent upgrades, BD3 with CCS has been able to operate for an extended period with emissions levels below the current federal carbon tax threshold, and far below the emissions intensity of BD3 without CCS (approximately 1,000 tonnes of CO2/GWh), as illustrated in this chart:

(Source: BD3 Status Update: Q1 2023 (saskpower.com))

Thus, the BD3 CCS facility is providing a double shot of benefits in the form of carbon tax cost savings for Saskatchewan residents while keeping CO2 out of the atmosphere as part of the effort to address global climate change.

At the same time, more than 500,000 tonnes of CO2 from BD3 have been directed to the Aquistore project – the world’s largest geological research site for CO2 storage – that is demonstrating how CO2 can be safely and permanently sequestered more than three kilometres underground in saltwater-infused sandstone formations.

The Knowledge Centre continues its strong collaboration with SaskPower to optimize the use of CCS at BD3 and continue to improve the CCS facility’s efficiency in an economically sustainable manner. Meanwhile, the valuable knowledge and experience we have gained through the design, construction, operation and improvements of CCS at BD3 continue to make us a globally recognized resource for the development of new projects in a wide range of industries, including power generation, mining, cement manufacturing, oil and gas production, forestry, and chemical processing.

Ultimately, our goal is to help the next generation of CCS projects learn from this first of a kind project to capture CO2 more effectively, with minimal risk, and lower cost. That’s something everyone can be proud of.