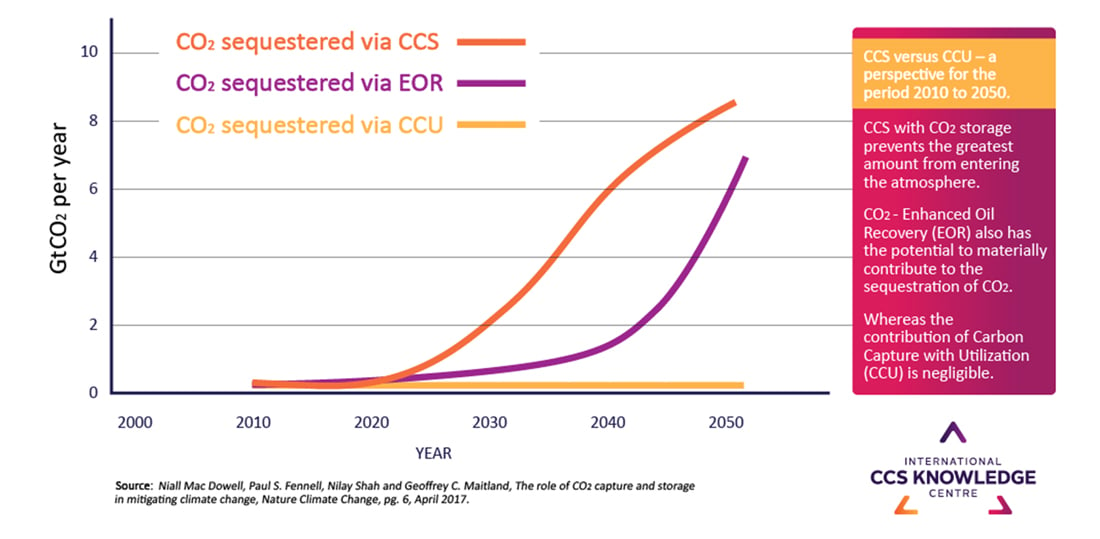

CCS Makes the Largest Impact in Mitigating Climate Change

Why Capturing CO2 Matters?

CCS is a game-changer in reducing industrial carbon emissions, making it a key technology in our global effort to reach net-zero emissions by 2050.

By capturing and storing CO2, we can significantly cut down on the harmful gases released into our atmosphere, protecting our planet for future generations.

Major global organizations, including the International Energy Agency and the UN’s Intergovernmental Panel on Climate Change (IPCC), have stated that many countries won’t hit their emission reduction targets without large-scale CCS. Studies show that without it, the cost of climate mitigation could skyrocket by 138%.

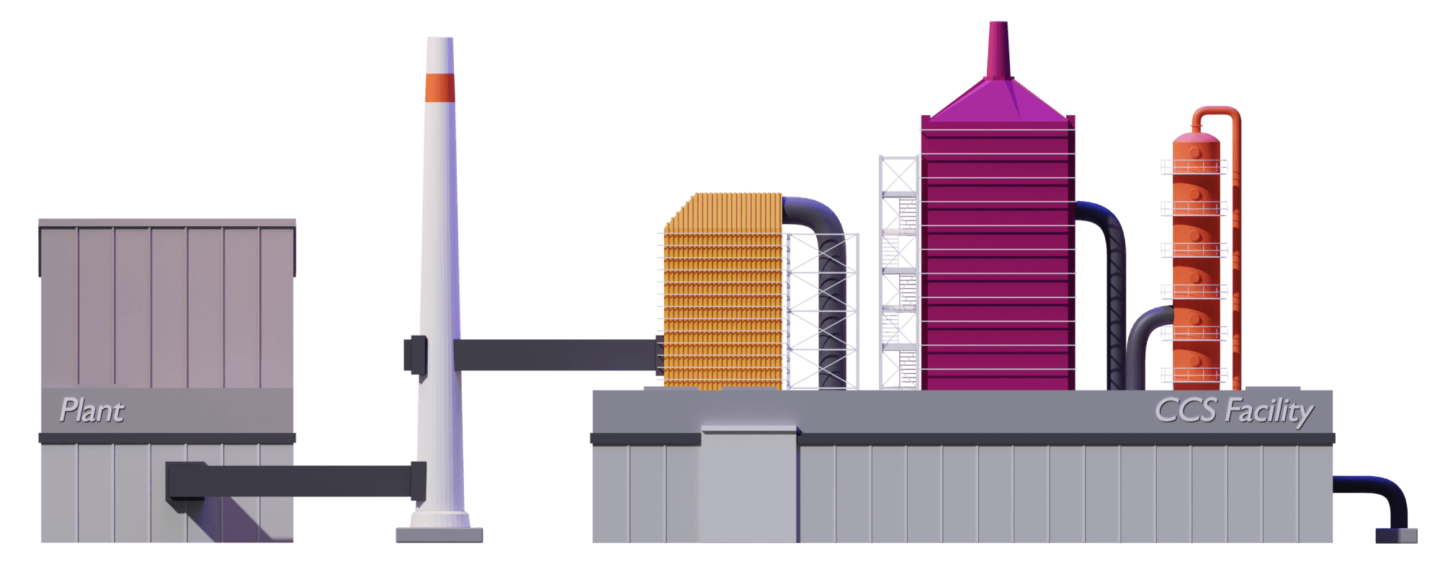

How Does the Capture Process Work?

There are a variety of capture processes, but most commonly the process of capturing CO2 uses solvents and a fascinating blend of chemistry and engineering. It all starts with flue gas, a byproduct of industrial processes, being directed into a large vessel called an absorber. Inside this absorber, there are layers of structured metal packing that are designed to maximize the interaction between the gas and a liquid solvent which is a blend of water and a chemical known as amine.

Here’s where the chemistry kicks in: the amine is introduced into the absorber. The amine specifically targets CO2 in the gas stream, reacting with it and absorbing the CO2 into the liquid. This CO2-rich liquid then collects at the bottom of the vessel. Next, the CO2-laden amine is sent to a second vessel called a stripper. In the stripper, the liquid is heated which produces steam. The steam rises up through the vessel and ‘strips’ the CO2 from the solvent. The amine, now free of CO2, is recycled back into the absorber to repeat the process and capture more CO2.

Finally, the released CO2 gas is compressed into a supercritical state—a dense, fluid-like form that makes it easier to transport. The CO2 is then sent through pipelines to be either permanently stored underground or utilized for EOR. This process not only captures CO2 efficiently but, the recirculation of amine, also ensures the continuous operation of the capture system, bringing us closer to a sustainable future and cutting emissions from reaching the atmosphere.

Components of a Carbon Capture Facility

Industrial or Power Plant

Flue Gas Stack

Flue Gas Duct

Flue Gas Pre-Treatment

CO2 Absorber

CO2 Stripper

CO2 Transport Pipe

Why is Large-Scale CCS Important?

As CO2 levels in the atmosphere continue to climb due to human activity, our planet faces unprecedented climate challenges. While renewable energy and increased efficiency are crucial steps, they alone won’t achieve the deep CO2 reductions we need right now. This is why CCS has become one of the solutions for the high emitting industries.

CCS isn’t just for the energy sector; it’s an option for industries with few other options to reduce emissions, such as iron and steel production, cement manufacturing, and agriculture. These sectors not only generate CO2 from fuel use but also produce it as an unavoidable byproduct of their processes. For some of the world’s most carbon-intensive industries, CCS may be the most viable path for achieving emissions reductions.

One of the advantages of CCS is that it can be integrated into existing energy and industrial infrastructures. This allows countries to decarbonize their electrical grids and transition to carbon-free energy systems more gradually, without sacrificing economic stability.

By enabling the retrofit of current infrastructure, CCS provides the flexibility and time needed to make the transition to cleaner energy systems. It supports the preservation of industries that employ millions globally, making it not just a technological solution, but also an economic one.

In addition, CCS is part of the global strategy to achieve deep emissions reductions.