The International CCS Knowledge Centre (Knowledge Centre) is working with the University of Regina (UofR) on an important study to examine the performance of post-combustion (PCC) carbon capture and storage (CCS) systems that uses a unique online interface to analyze amine solvent chemistry and the impacts of fly ash on the amine degradation process.

With a global focus to significantly reduce and prevent carbon dioxide (CO2) emissions in the atmosphere and with nearly 38 per cent of world electricity being derived from coal-fired power plants, it is critical to advance improvements to carbon capture technology.i

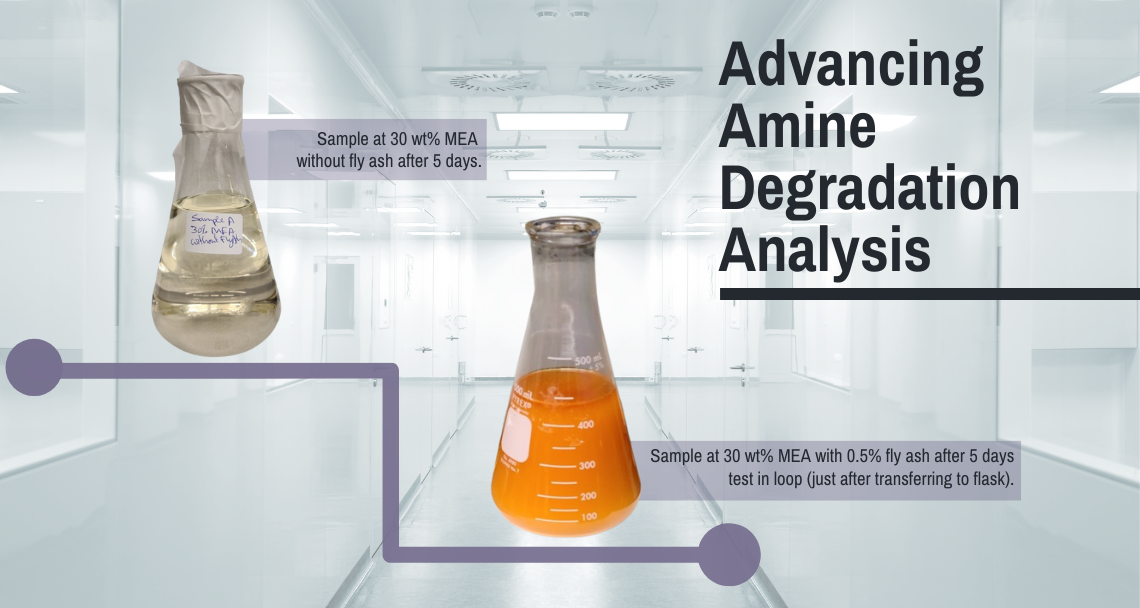

The risk of accelerated amine degradation is a barrier to applicability and deployment of large-scale CCS. Additionally, the potential impact of fly ash is an important consideration for the economic operation of post-combustion CO2 capture.

“The cost of solvent replacement due to rapid degradation is a major consideration for the feasibility of a CCS operation that is weighted against the cost of cleaning up flue gas streams, which includes fly ash removal,” says Yuewu Feng, Senior Engineer at the Knowledge Centre. “Research analyzing amine solution degradation and the impacts caused by fly ash contamination is still limited so we are excited to join forces with Dr. Amr Henni and the team (Dr. Devjyoti Nath and Firuz Philip) at the UofR’s Faculty of Engineering and Applied Science on this much-needed project.”

Fly ash results from the separation of dust particles in flue gases produced in pulverised coal-fired furnaces, such as coal-based thermal power plants. While fly ash can be a valuable by-product that is saleable for use in manufacturing building materials, such as cement, it contains various transition metals, which are believed to behave as a catalyst for amine degradation.

Continuous Results in Real Time

An online system was developed to remotely study the amine solvent chemistry in near real time. The system includes a Gas Chromatograph (GC) equipped with a liquid sample delivery system to analyze the aqueous amines: monoethanolamine (MEA), Methyl diethanolamine (MDEA) and their mixtures at different concentrations and temperatures. GC is a standard technique used in laboratories. The equipment is capable of directly measuring numerous primary parameters desired, including amine and water concentration, CO2 and degradation.

“To date there is very little online instrumentation available for the analysis of amine solvents. Although new technologies are being developed, they are difficult to establish as they typically use techniques that do not directly measure the parameters of interest, which also increases their complexity,” says Colin Campbell, Chemist to the Knowledge Centre.

“Using this method allows us to acquire samples directly from the process streams for analysis, which leaves less room for error in our analysis and can provide timely, high quality data.”

Aside from improving accuracy and reducing labor costs, results can be provided on a continuous basis to an operator interface, allowing plant personnel to react in a timely fashion without physical collecting and analyzing samples.

“We no longer have to wait for someone to physically conduct the sampling and then wait hours and sometimes days for a laboratory result – a major improvement in our measurement methods,” says Campbell.

This technique is also useful for developers of newer online analytical measurement equipment as it can provide high-quality data to compare against other approaches that typically use less direct measurements of the parameters of interest.

How it Works

CO2 capture with an aqueous amine-based solvent is one of the most common and advanced technologies for post-combustion CO2 capture. Amine solvents are used to separate CO2 from other components of a flue gas to capture CO2 through a chemical reaction after a flue gas stream is generated from the fuel combustion process.

The first step in this project requires the fly ash to be fully characterized by particle size distribution and trace element composition, sieved, and then mixed in different amounts with the amine solution at different CO2 partial pressures. From there, the online system will be used to estimate the degradation of the different amine solutions based on the results obtained before and after contact with different fly ash amounts at different temperatures.

To date, the online sampling system has performed well in ` long duration testing and provided information about water and amine concentrations, as well as CO2 loading, which can allow for the estimation of the percentage of amine degraded.

Next Steps

Accelerated degradation, which is contributed to by fly ash contamination has been reported to greatly increase the consumables portion of the cost of CO2 capture. As outlined in the Shand CCS Feasibility Study, the cost of consumables and (Operations, Maintenance & Administration (OM&A) represents 15 per cent of the cost of capturing CO2. ii

“This project is specifically geared toward providing better tools for the chemical analysis of CCS solvents in production and large-scale testing facilities,” says Feng. “The short-term objective is to use the developed online solvent analysis system in a pilot plant prior to installing the equipment on a large-scale facility for further testing and doing so for an extended period.”

There will be several recommendations for the use of this type of analytical instrumentation in real world process environments and a paper on this study will be developed and presented at the 15th International Conference on Greenhouse (GHGT-15) Gas Control in March 2021.

Read the full abstract: A Novel Methodology for Online Analysis of Amine Solution Degradation Caused by Fly Ash

[i] World Coal Association: “Coal plays a vital role in electricity generation worldwide. Coal-fuelled power plants currently fuel 38% of global electricity and, in some countries, coal fuels a higher percentage of electricity.” https://www.worldcoal.org/coal/uses-coal/coal-electricity

[ii] The International CCS Knowledge Centre. The Shand CCS Feasibility Study. https://bit.ly/2ndGen-CCS