by Zewei Yu, Senior Advisor, Asia Relations

International CCS Knowledge Centre

China’s announcement of carbon peaking before 2030 and neutrality before 2060 is ambitious and inspiring. In order to meet such an enormous commitment, low-carbon solutions will be required for all energy intensive industry sectors, including the steel industry. Carbon capture utilization and storage (CCUS) will play a critical and evolving role for China’s energy transition as a competitive companion to other clean energy pathways. China may have to rely on an energy mix including decarbonized fossil fuel-based clean energy with low- to no-carbon emissions during its energy transition.

CCUS is Needed for the Steel Industry

The steel sector is facing rising pressure to reduce its carbon footprint worldwide, as iron and steel making processes are energy and carbon intensive. The steel sector is currently the largest industrial consumer of fossil fuels, mainly coal, which is used both as a feedstock and an energy source to generate heat and make coke. This is an essential ingredient in the chemical reactions necessary to produce steel from iron ore. The iron and steel sector directly accounts for 7 % (2.6 gigatonnes [Gt]) of carbon dioxide (CO2) emissions annually, and 8% of the global total energy demand. Global demand for steel is projected to continue to increase by more than a third through to 2050, especially in emerging economies such as Asia, where high populations require more infrastructure.i Meeting this growing demand presents an enormous challenge as the iron and steel sector seeks a sustainable and competitive path forward.

Recent IEA projections indicate that, by 2050, cumulative direct emission reductions by CCUS will account for 16% of global iron and steel emissions reduction, requiring 400 megatonnes (Mt) of CO2 capture capacity each year.ii CO2 capture through demonstration is a mature, and proven, technology that can be adapted to various industry sectors. Existing steel production facilities with a blast furnace and a basic oxygen furnace (BF-BOF) can be retrofitted to aid in emission reductions. CCUS retrofits should focus on the relatively young BF-BOF steel making process, if energy and climate goals are to be achieved.

The world’s first large-scale commercial CCUS project with iron and steel mill was developed in the United Arab Emirates (UAE) in 2016; the Abu Dhabi CCS Projectiii capturing 800,000 t/y of CO2. The CCUS applications to a Direct Reduction Iron (DRI) process mill is advantageous for it generates a flue gas streams with very high concentrations of CO2 (up to 90% for efficient capture), from combusting reformed reducing gas fuel from natural gas. The captured CO2 is then piped to oil fields for use in enhanced oil recovery (EOR) and storage. This offers a business model more than a conveniently applicable pathways for the BF-BOF process. Of the approximately 1.3 Gt of iron produced globally in 2018, merely 8% were made using the DRI process, of which 70% are located in natural gas abundant Middle East and India. iv

Enabling CCUS Potential for Steel Industry in China

Among the various options available to reduce its carbon footprint, CCUS remains one of the most effective for China to achieve deep emission cuts, including replacing its long process with a lower emission short electric furnace in the long term.

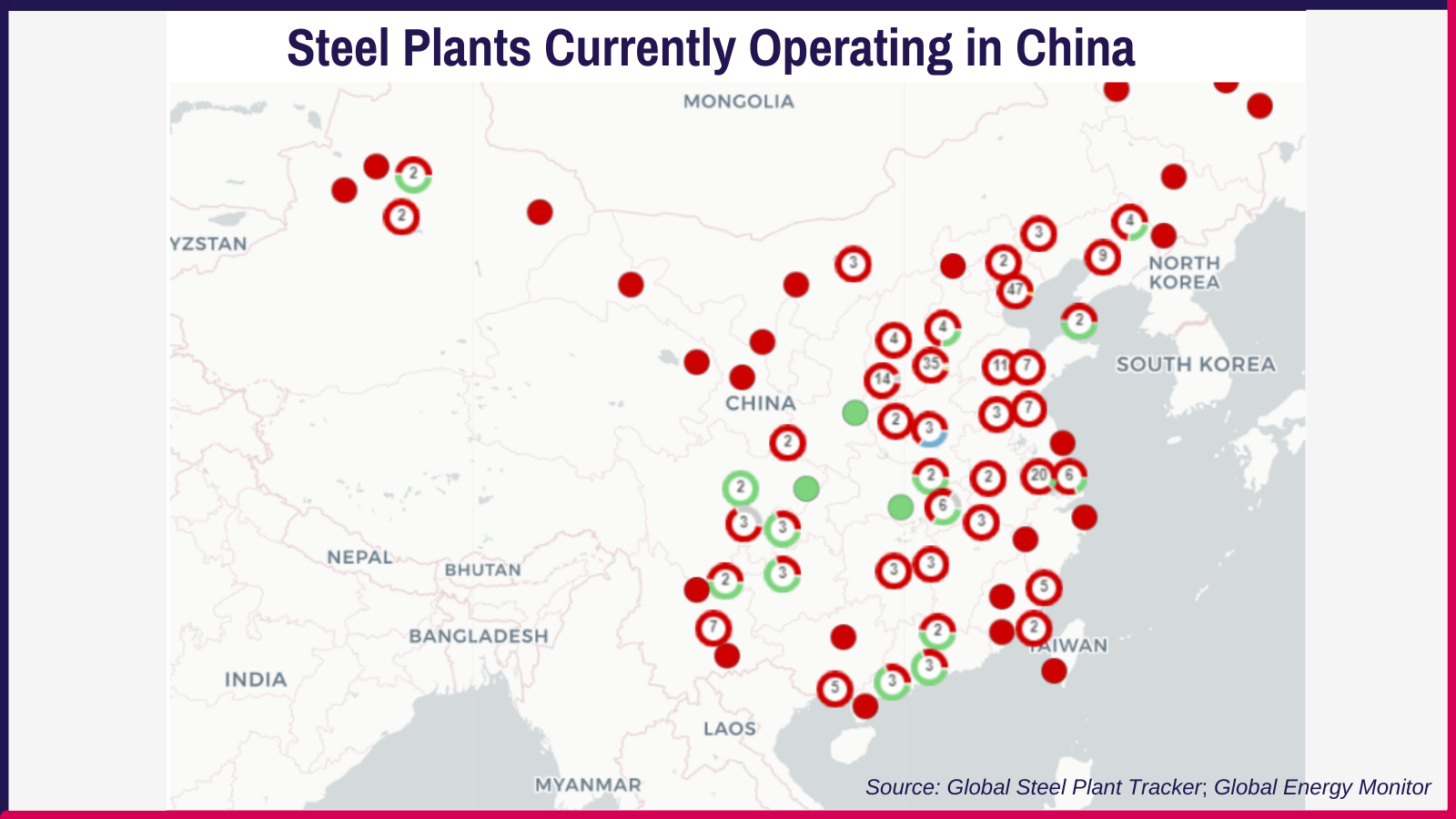

According to the World Steel Association, 70% of crude steel was made from long BF-BOF processes. Of the over 1.8 Gt of total crude steel produced globally in 2018, 997 Mt (50%) was produced in China.v Eighty-eight percent of its crude steel was produced from BF-BOF processes, and 12% from the short electric furnace process which has a lower carbon footprint (well below the 30% of the world average).vi The long BF-BOF process produces about 2.3 tonnes of CO2 per tonne of steel for all direct and indirect emissions.vii

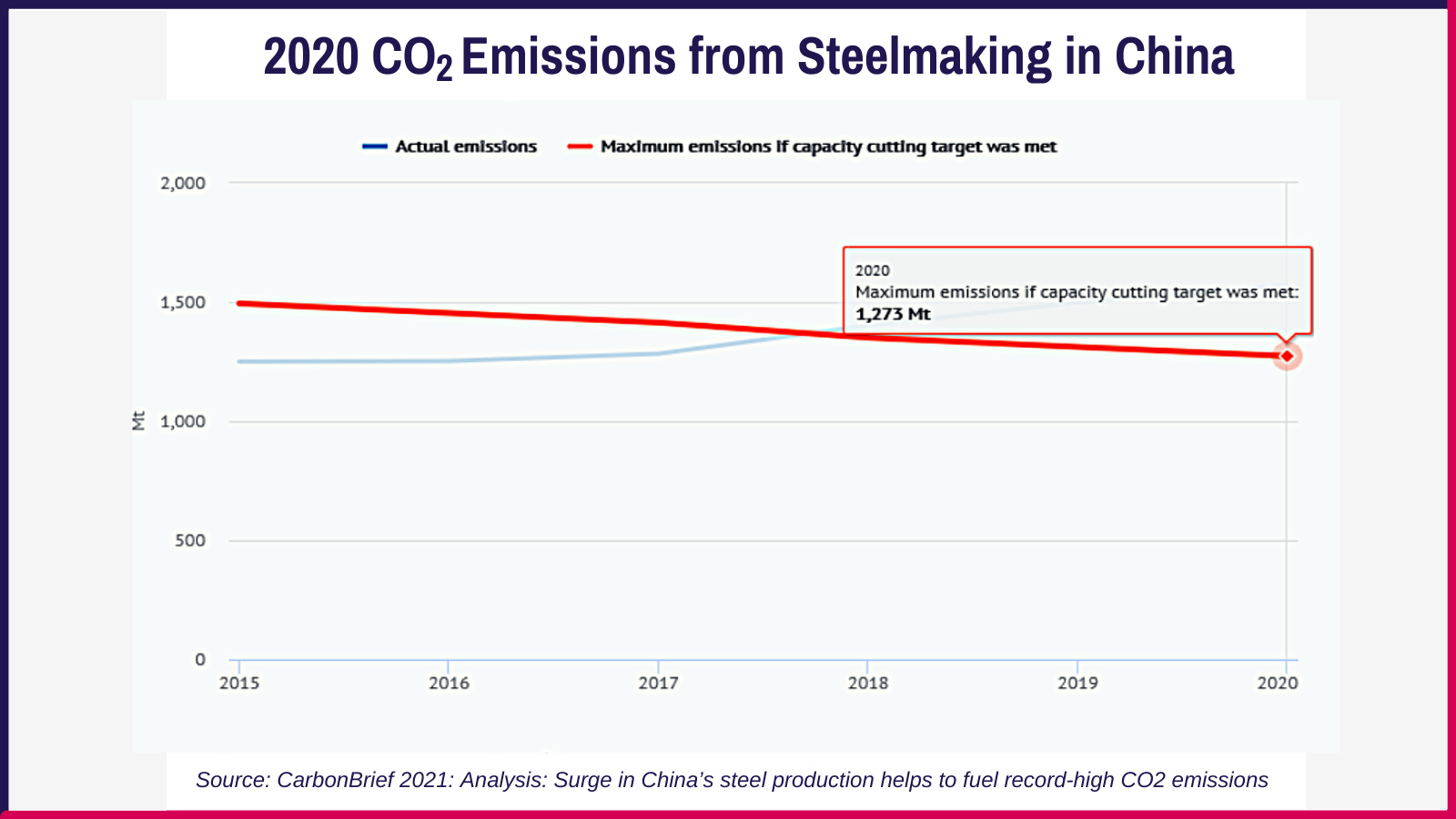

In 2017, China’s key target set for the steel industry under the “supply side structural reforms” was to limit the steel production capacity to less than 1 Gt by 2020, according to China’s Ministry of Industry and Information Technology’s (MIIT) Steel Industry Adjustment and Upgrading Plan for 2016-2020, which is in charge of managing steel over-capacity.viii

Predictions for 2020, for the emissions from steel making were to be close to 1.3 Gt of CO2e if the capacity reduction targets were met. However, the actual emissions from output are anticipated to be reported closer to 1.5 Gt, consisting of 15% of the total anthropogenic emissions of China.x

Switching CCUS technology application to the predominant BF-BOF process is a major opportunity, as well as challenging for China’s young steel industry infrastructure for its greenhouse gas (GHG) emission reduction pathways. The steel industry could meet the challenges and make CCUS an opportunity of transition to sustainable future by crossing sector barriers for cooperation with industry sectors such as petroleum, coal chemicals, and power generations, who already have developed transferable know-how in CCUS technology applications at piloting scales. CCUS would be made easier in coordination with innovations in other industry sectors, as well as in policy approach and business model.

Collaboration, Policy Parity Needed to Accelerate CCUS

In 2015, a feasibility study of a post-combustion CCS system based on coal-fired power generation was demonstrated at a pilot scale on a typical BOF process at Shougang-Caofeidian near Beijing. Typically, a conventional BOF process has multiple flue gas sources of CO2 emissions of different concentrations and chemical compositions. Therefore, the CO2 capture system used in the feasibility study tested flue gases mixed from more than one selected emissions source. The lime kiln and heating ovens (hot blast stoves) represent flue gas streams similar to emissions from cement and coal-fired power facilities, but with higher CO2 concentrations; while the flue gas emitted by the co-generation plant and coke oven is also similar in CO2 concentration but high emission volume. This project demonstrated that the carbon capture system can further be applied to a BF-BOF long iron making process with multiple emissions sources.xi

Government & Industry Priorities

The iron and steel sector itself will not bring about a sustainable transition on its own. Globally, the current financial incentives and regulatory frameworks have not been sufficient to spur large scale projects in the steel industry. Decision makers should have 2030 in mind as the critical window to accelerate the transition. Governments will play a central role, especially in the scenario of continued downsizing from overcapacity and recovery from the current economic recession. The steel industry is expected to implement tremendous changes to remain competitive amid a high-pressure market in the next decade.

High-level priorities for governments and industry is to fast-track CCUS demonstration project development within the next decade, across industry sectors, to further incentivize policy parity with renewable energy. The most remarkable success in energy technology in China has been the domestic deployment of wind and solar power, and its global spillover effects. To accomplish its newly announced goals to prioritize large-scale CCUS deployment as a tool towards meeting its emissions peaking challenge in this decade, China may consider emulating its successful experiences in developing renewable energy for CCUS development.

China needs to prioritize developing the market for captured CO2 and infrastructure for its transportation, use and storage, including pipeline and oilfield infrastructure for EOR and geological storage, as a driver for upscaled CCUS demonstration and optimization. It is imperative to develop a full chain CCUS cluster in key regions near both sinks and sources on the fringes of the basins, and infrastructure that will allow multiple sources of captured CO2 to share at low cost. Prioritized CO2-EOR /storage is like a consumer market rewarding early mover deployment projects of both strategic energy security and climate benefits.

Learning from large-scale CCUS demonstration projects, specifically from such projects, as the Boundary Dam 3 CCS Facility, will provide China with the opportunity to be a CCUS leader across sectors in the next five years, supplying a competitive low-carbon technology solution applicable to its own industries and to those in the Asia Pacific region and beyond. Internationally available learnings could be transferrable to facilitate CCUS demonstration and deployment in China from the full chain cluster of large-scale CCUS projects in operation that have proven successful and viable.

i IEA. 2020. The IEA Steel Industry Technology Roadmap https://www.iea.org/reports/iron-and-steel-technology-roadmap

ii IEA. 2020. Cumulative Direct Emission Reductions by Mitigation Strategy 2020-2050 https://www.iea.org/data-and-statistics/charts/cumulative-direct-emission-reductions-by-mitigation-strategy-in-the-sustainable-development-scenario-between-2020-and-2050

iii CSLF. 2017. Case Study: Al Reyadah CCUS Project PowerPoint Presentation.https://www.cslforum.org/cslf/sites/default/files/documents/AbuDhabi2017/AbuDhabi17-TW-Sakaria-Session2.pdf

iv World Steel Association. 2019. World Steel Statistics Data 2019.https://www.worldsteel.org/zh/dam/jcr:96d7a585-e6b2-4d63-b943-4cd9ab621a91/WSIF_2019_CN.pdf

v World Steel Association. 2019. World Steel Statistics Data 2019. https://www.worldsteel.org/zh/dam/jcr:96d7a585-e6b2-4d63-b943-4cd9ab621a91/WSIF_2019_CN.pdf

vi Science and Technology Daily, 2021-01-04. Carbon Emission Reduction Crux for Ecological and Environmental Conservation during 14th Five-year Period, and for a National Roadmap for Low Carbon Transition http://www.tanpaifang.com/jienenjianpai/2021/0104/76112_3.html

vii GCCSI. 2017: https://www.globalccsinstitute.com/news-media/insights/ccs-a-necessary-technology-for-decarbonising-the-steel-sector/

viii CarbonBrief. 2021. Analysis: Surge in China’s steel production helps to fuel record-high CO2 emissions. https://www.carbonbrief.org/analysis-surge-in-chinas-steel-production-helps-to-fuel-record-high-co2-emissions/amp

ix CarbonBrief. 2021. https://www.carbonbrief.org/analysis-surge-in-chinas-steel-production-helps-to-fuel-record-high-co2-emissions/amp

x CarbonBrief. 2021. https://www.carbonbrief.org/analysis-surge-in-chinas-steel-production-helps-to-fuel-record-high-co2-emissions/amp

xi GCCSI. 2015. Applying Carbon Capture and Storage to a Chinese Steel plant. https://www.globalccsinstitute.com/archive/hub/publications/195933/Applying%20carbon%20capture%20and%20storage%20to%20a%20Chinese%20steel%20plant.pdf