As published in the February 2021 International Cement Review

While the cement and concrete industry has been working for decades on improving technology to create sustainable products and reduce carbon emissions, significant inroads in emissions reduction remain a challenge. However, large-scale carbon capture and storage (CCS) is a solution for hard-to-abate sectors, such as cement.

Canada-based cement producer Lehigh Cement, part of HeidelbergCement-owned Lehigh Hanson, and the International CCS Knowledge Centre (the Knowledge Centre) are pioneering a joint study to examine the feasibility of a full-scale carbon capture and storage (CCS) facility at the Lehigh cement plant in Edmonton, Alberta, Canada.1

A first for the North American cement industry, the initiative looks at the viability of capturing the majority of the CO2 from the cement plant’s flue gas. The study targets a 90-95 per cent capture rate – an estimated 600,000tpa of CO2.

Applying power sector experience

To complete the study, the Knowledge Centre will apply the experience gained through the design, construction, operation and subsequent enhancements/ modifications of the SaskPower Boundary Dam 3 Carbon Capture and Storage Facility (BD3 CCS Facility), the world’s first post- combustion CCS facility on a coal-fired plant.

“With this full-scale initiative, the application of CCS moves its value beyond power plants into cement, helping accelerate deployment of this urgently needed technology across energy and industry systems,” says Beth Hardy Valiaho, vice-president of Strategy & Stakeholder Relations at the Knowledge Centre.

“In sharing experience-based knowledge from the world-renowned BD3 CCS Facility, we can help global leaders, such as HeidelbergCement, realise the capital cost and risk reduction associated with second-generation CCS.”

The Knowledge Centre’s Shand CCS feasibility study2 shows a 67 per cent capital cost reduction per tonne of CO2 captured, with more than a 90 per cent capture rate potential.

Supporting HeidelbergCement’s drive for CO2-neutral concrete

Joerg Nixdorf, president of Lehigh Hanson’s Canada Region, says CCS has the potential to support HeidelbergCement’s goal of achieving CO2-neutral concrete by 2050 at the latest and make it the most sustainable building material.

Lehigh Hanson’s emission reduction targets are outlined in the HeidelbergCement Sustainability Commitments 2030,3 which are based on the UN Sustainable Development Goals as well as recommendations from the International Energy Agency (IEA) Sustainable Development Scenario. These commitments include reducing the specific net CO2 emissions/t of cementitious material by 30 per cent compared to 1990 by 2025 – five years before its initial target date. To achieve this, the company has defined concrete CO2 reduction measures for all plants worldwide and also implemented a focus on permanently reducing all other air emissions below the cement industry average.

“CCS has the potential to become a major component in climate strategies because it is a proven suite of technologies. With the guidance of the Knowledge Centre, we will know the applications of this invaluable solution to significantly reduce GHGs and bring us closer to our low-carbon industry transition,” says Kent Stuehmer, vice president of Cement Operations for Lehigh Hanson’s Canada Region.

HeidelbergCement is also currently conducting carbon research projects at several of its operations worldwide – in Belgium, Germany, Morocco, The Netherlands and Norway. In particular, HeidelbergCement’s subsidiary Norcem is looking at applying CCS technology at its Brevik cement plant in Norway.

CCS as the key decarbonisation solution?

Next to water, concrete is the second most-consumed substance on the planet with ~3tpa/person. With the rise in global population and urbanisation, the 2018 International Energy Agency (IEA) Technology Roadmap – Low-Carbon Transition in the Cement Industry5 predicts an increase in cement production of between 12-23 per cent by 2050. With a contribution of 7-8 per cent of global CO2 emissions, the cement industry is well positioned to see the adoption of CCS as a decarbonisation solution.

Claude Lorea, cement director of the Global Concrete and Cement Association (GCCA), says that when it comes to tackling long-term sustainability and climate change goals in the cement industry, CCS and carbon capture, use and storage (CCUS) technologies are “definitely part of that equation.”

“CCUS has one of the greatest opportunities to reduce our sector emissions. We are seeing these CCUS projects flourishing in our industry,” noted Ms Lorea.

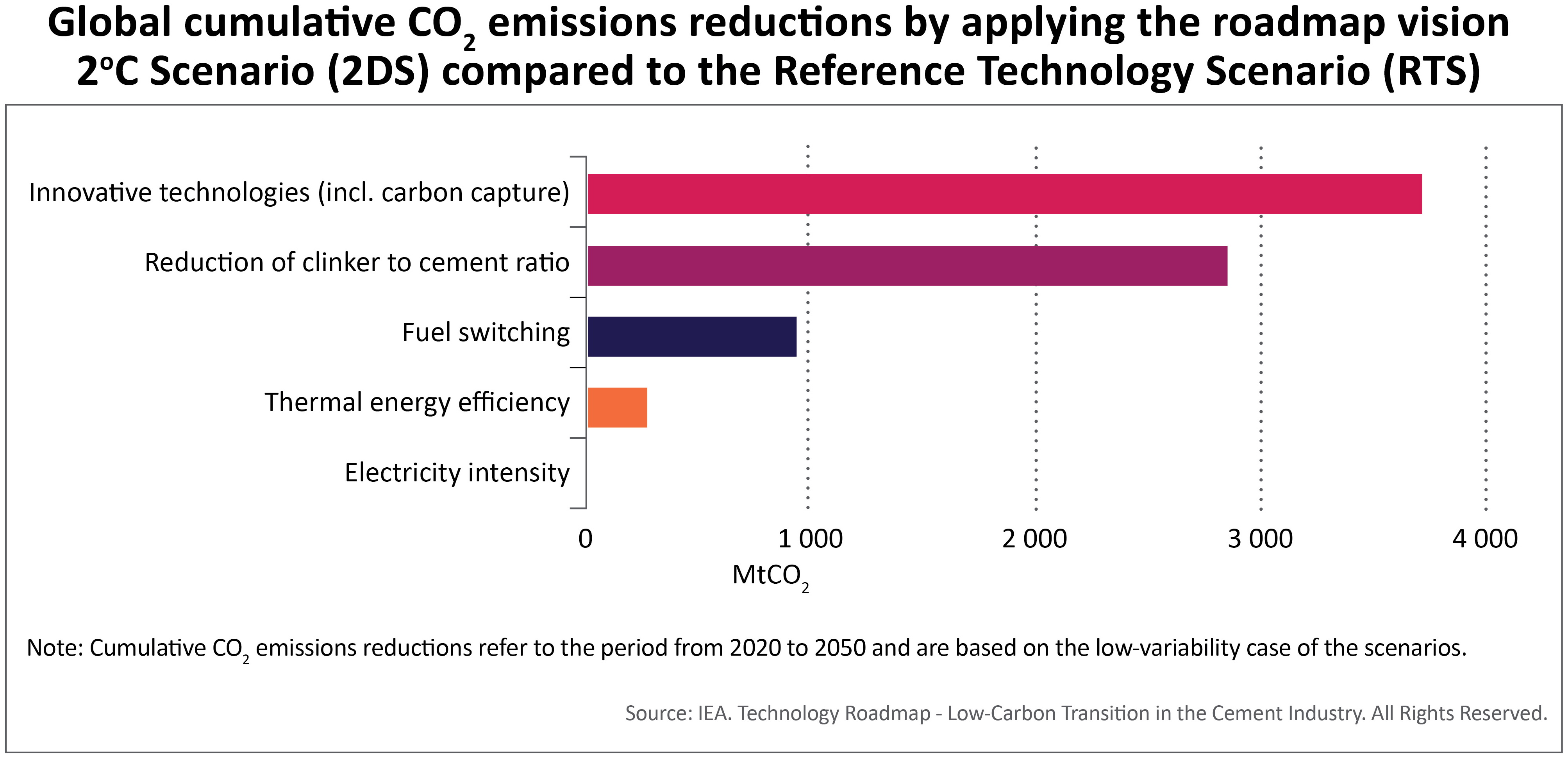

According to the same IEA report, integrating carbon capture into cement production is one of the main carbon mitigation levers supporting the sustainable transition of the cement sector. The integration of emerging and innovative technologies, such as carbon capture, has been identified to provide the largest cumulative CO2 emissions reduction of 48 per cent in its 2?C Scenario, compared to the IEA’s baseline Reference Technology Scenario, by 2050. To a lesser extent, reducing the clinker-to-cement ratio, switching to less carbon-intensive fuels and improving energy efficiency make up the remainder of the reduction.

Although industrial process emissions result from chemical or physical reactions and the need for high-temperature heat can be among the hardest to abate in the energy system, the expertise acquired at the BD3 CCS Facility can be adapted to sectors such as the cement industry due to the remarkable similarities in flue gases.

Additionally, the Shand study incorporates the concepts to reuse water recovered from the flue gas for cooling so that no new sources of water are required, as well as recovering waste heat from the existing process to minimise energy use. Both concepts are part of the current study and largely applicable to carbon capture projects in the cement industry. “Broader deployment of CCS facilities will lead to further reductions in risks and costs, and greater CCS investments. As we continue to build on and share our learnings with second-generation CCS, we can advance understanding of this critical technology across sectors and accelerate its deployment worldwide,” adds Ms Hardy Valiaho.

“As large-scale CCS could well become the definitive solution to cut GHG emissions in the cement industry, the Lehigh CCS Feasibility Study explores the value of this for the cement industry, by encompassing engineering designs, cost estimation […] and an in-depth business case analysis.”

The business case

As large-scale CCS could well become a definitive solution to cut GHG emissions in the cement industry, the Lehigh CCS Feasibility Study explores the value of this for the cement industry, by encompassing engineering designs, cost estimation in line with Association for the Advancement of Cost Engineering (AACE) Class 4 and an in-depth business case analysis. Development of a detailed business case and a budget for a front-end engineering design (FEED) study are currently underway. Following the completion of the feasibility study, a FEED study would provide a detailed engineering, design and integration to an AACE Class 3 estimate and complete the business case for a final investment decision.

Key to understanding sustainable output growth “This CCS feasibility study is essential for understanding how our industry can continue to meet growing production demands, while also meeting equally important climate targets. We are proud to be in a position to lead a global change with a crucial clean technology in our industry,” highlights Mr Nixdorf.

REFERENCES

1 INTERNATIONAL CCS KNOWLEDGE CENTRE (2019) Lehigh Cement and the International CCS Knowledge Centre Pioneering a Feasibility Study of Full-Scale Carbon Capture Storage (CCS) on Cement. http://bit.ly/2rz8Yf4

2 INTERNATIONAL CCS KNOWLEDGE CENTRE (2018) The Shand CCS Feasibility Study. https://bit.ly/2ndGen-CCS

3 HEIDELBERGCEMENT (sd) Sustainability Commitments 2030. https://www.heidelbergcement.com/en/sustainability-commitments-2030

4 COLUMBIA UNIVERSITY (2012) Emissions from the Cement Industry. https://blogs.ei.columbia.edu/2012/05/09/emissions-from-the-cement-industry/

5 IEA (2018) Technology Roadmap – Low-Carbon Transition in the Cement Industry. Paris, France: IEA. https://www.iea.org/reports/technology-roadmap-low-carbon-transition-in-the-cement-industry

PDF version as featured in the February 2021 issue of the International Cement Review