Originally published by American Coal Council

American Coal magazine Issue 1, 2020

Post-combustion carbon capture and storage (CCS) is impartial. It is a suite of technologies that can be applied – yes, to coal – but likewise to other industries also wanting to see substantial cuts in their carbon dioxide (CO2) emissions.

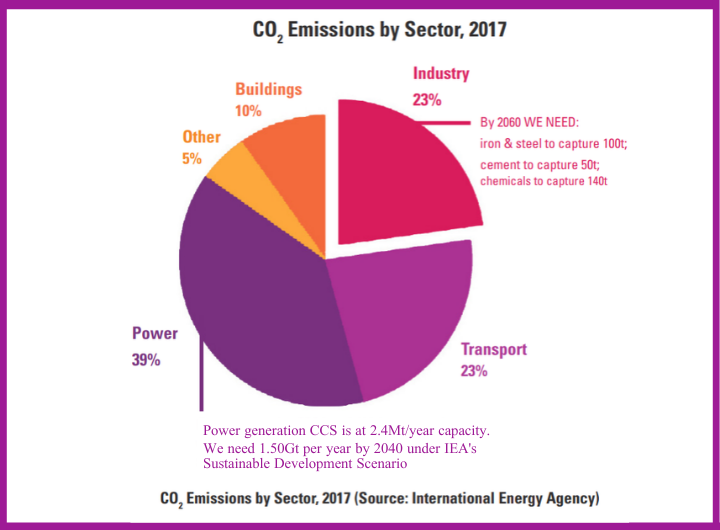

One of the misconceptions of the drive toward climate action is the oft-misdirected targeting of sectors. Alternatively, it is the emissions associated with sectors that are the center-point to lessen anthropogenic greenhouse gases (GHGs). As coal, along with oil and gas, are bastions in power and energy, so are cement and steel for industrial areas. So, to achieve global emission reductions goals while also fostering prosperity, rapid and wide adoption of large-scale CCS is needed across sectors.

FOUNDATION LEARNING COMES FROM CCS ON COAL

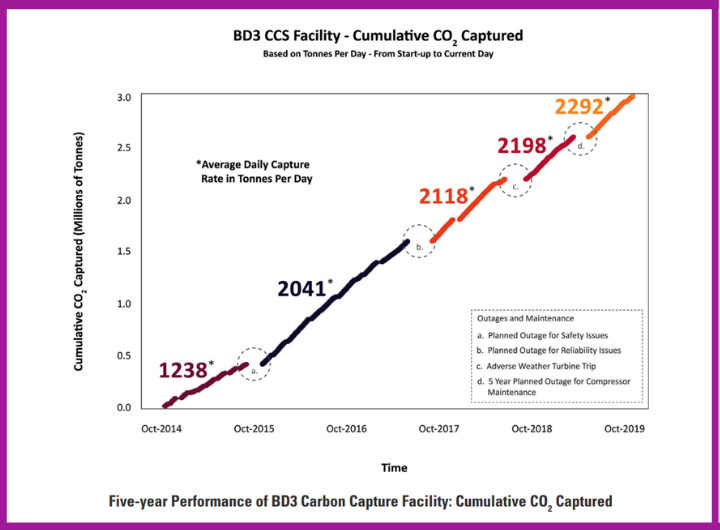

With operations commencing in October 2014, SaskPower’s Boundary Dam 3 CCS Facility (BD3) located in southern Saskatchewan, Canada, was the first in the world to have postcombustion CCS on a coal plant.

The BD3 project refurbished the 45-yearold unit (including a replacement of the steam turbine and generator), extending it for an additional 30 years of service and modifying it to work with the CCS plant (including a unit for flue gas pre-treatment to remove sulfur dioxide and particulate). BD3 was designed at a 90 percent capture rate, reducing the CO2 emissions to 120- 140 tonnes/GWh. In the fall of 2019, BD3 surpassed a milestone of 3Mt of captured and stored CO2.

BD3’s evolution to success is a testament that learning comes from doing. This is why, in 2016, SaskPower and BHP founded the International CCS Knowledge Centre (Knowledge Centre)– to share the rich expertise from BD3 with the world.

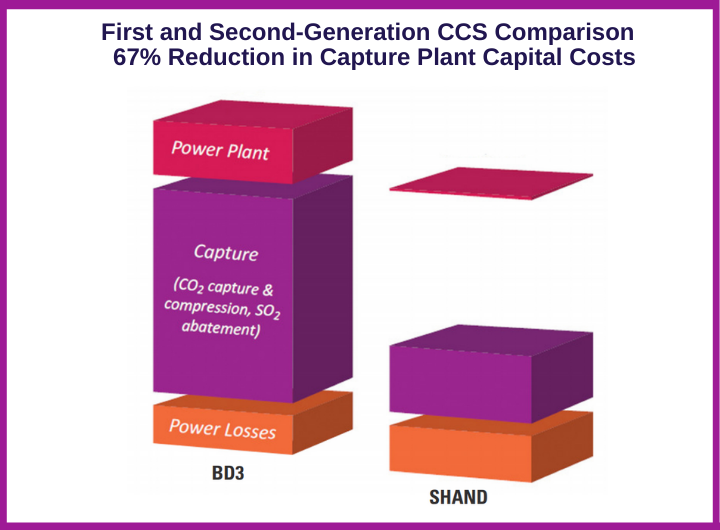

SECOND-GENERATION CCS

Setting a precedent in large-scale carbon capture, BD3 was the foundation for the Knowledge Centre’s second-generation CCS study, the Shand CCS Feasibility Study (Shand Study) – which is based on the Shand Power Station, a 28-year-old neighboring coal-fired plant. The study revealed capital costs for the next plant to be 67 percent cheaper per tonne of CO2 captured.

Economies of scale contributed to cost savings by scaling from a 150-megawatt (MW) unit at BD3 to Shand’s 305 MW unit. The calculated cost of capture, identified in the study, was USD$45/tonne of CO2 based on: a 30-year sustained run-time of the power plant; its modifications to integrate CCS; plus the generation loss due to the addition of the capture plant; as well as the capture island capital costs, operation, maintenance and consumables.

Other key findings from the Shand Study include: a capture rate of up to 97 percent at reduced load while the plant integrates with renewable electricity supplies; an ability to capture CO2 at different plant outputs; and an ability to satisfy the additional water requirements solely by using flue gas condensate, simultaneously preventing a new waste water stream.

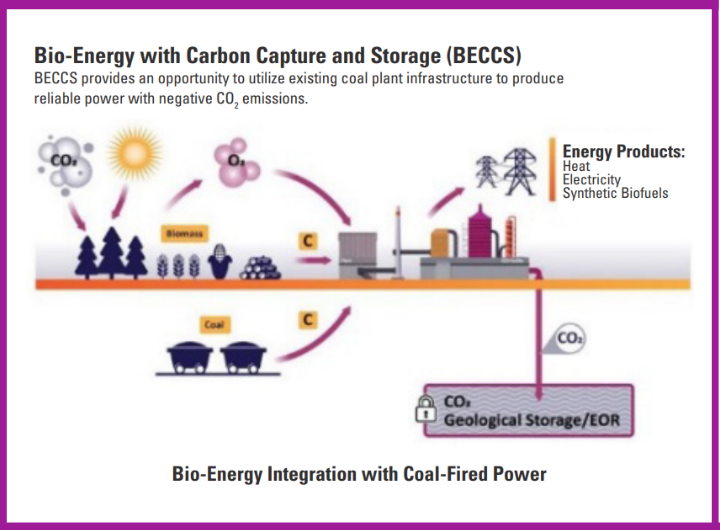

BEYONG COAL ?— CCS WITH BIOMASS

The Knowledge Centre further explored the findings of their Shand Study and evaluated the potential impact of bioenergy with CCS. Bioenergy is energy produced from renewable, biological sources, such as agriculture and forestry waste products. When bioenergy is combined with CCS it is known as BECCS – and when these two technologies work in tandem, emissions move to the negative side of the equation.

The conversion of existing coalfired power plant infrastructure to burn biomass provides an opportunity to have a low-cost and staged transition to lower emission energy sources.

As CCS can be used on a variety of flue gas streams, many of the findings from the Shand Study can be further applied to post-combustion capture on industrial processes, such as cement, steel and chemical manufacturing.

BEYOND COAL ?— CCS FOR NATURAL GAS

Natural gas generation is often promoted as a solution for emission reduction in the energy sector. Yet while its emission profile is much lower than unabated traditional coal plants, natural gas combined-cycle (NGCC) plants still have a significant CO2 footprint. New builds present a limiting factor as emission rates are locked in for the anticipated life of the plant.

The energy sector has the potential to drive accelerated emission reductions with the addition of CCS on NGCC plants. As natural gas with carbon capture can use postcombustion capture (PCC) technology, the lessons from current operating CCS facilities such as BD3 can contribute to their success. PCC technology on natural gas faces fewer technical hurdles in part because the emissions from gas contain fewer contaminants. There are several capture technologies being developed for natural gas around the globe, with many projects underway in Western Europe.

The U.S. is also seeing value in examining CCS on NGCC. In September 2019, the Department of Energy selected nine projects to receive $55.4 million3 in federal funding with cost-shared research and development for large-scale CCS projects. These projects support frontend engineering and design (FEED) studies for commercial-scale CCS on natural gas and coal power plants.

BEYOND COAL ?— CCS FOR INDUSTRY

The physics and economics governing the design and operation of thermal power plants are remarkably similar throughout the world. As CCS can be used on a variety of flue gas streams, many of the findings from the Shand Study can be further applied to postcombustion capture on industrial processes, such as cement, steel and chemical manufacturing.

Industrial CO2 emissions represent 24 percent of global CO2 emissions, 4 with the cement industry responsible for 1/3 of this, or as much as 8 percent of global emissions. Cement emissions are often considered difficult to cut as more than half of the emissions are process related – the CO2 is released by a chemical reaction and cannot be eliminated by changing fuel or increasing efficiency. Cement production is therefore a natural candidate for post-combustion carbon capture.

In an effort to cut GHGs, Lehigh Cement and the Knowledge Centre are conducting a feasibility study of a commercial-scale CCS project on Lehigh’s Edmonton, Alberta cement plant. With a CAD$1.4 million investment from Emissions Reduction Alberta, the CAD$3 million study will encompass engineering designs and cost estimation (at an AACE Class 4) for treatment of all of the plant’s emissions.

RETROFITTING FOR CCS SAVES MONEY AND REDUCES EMISSIONS

With the addition of a CCS facility, current assets (whether on cement, coal or other industrial plants) can be retrofitted, thereby supporting sectors in their GHG reduction goals while helping avoid costly and complex transformations.

REFERENCES

1. The International CCS Knowledge Centre, “The Shand CCS Feasibility Study Public Report,” November 2018, https:// ccsknowledge.com/resources/publications

2. CSIRO, Australia, “Towards Zero Emissions CCS in Power Plants Using Higher Capture Rates or Biomass,” IEA Greenhouse Gas R&D Programme (IEAGHG) Technical Report (2019-02), https://ieaghg.org/ publications/technical-reports. UK: IEAGHG, 2019

3. U.S. Department of Energy, Office of Fossil Energy, “FOA 2058: Front-End Engineering Design (FEED) Studies for Carbon Capture Systems on Coal and Natural Gas Power Plants,” https:// www.energy.gov/fe/foa-2058-front-endengineering-design-feed-studies-carboncapture-systems-coal-and-natural-gas

4. International Energy Agency (IEA), Paris, “World Energy Outlook 2017,” https:// www.iea.org/weo2017/ Coal co-firing with biomass is being done throughout the world and accommodates the development of biomass supply. Beyond Coal – CCS for Natural Gas Natural gas generation is often promoted as a solution for emission reduction in the energy sector. Yet while its emission profile is much lower than unabated traditional coal plants, natural gas combined-cycle (NGCC) plants still have a significant CO2 footprint. New builds present a limiting factor as emission rates are locked in for the anticipated life of the plant. The energy sector has the potential to drive accelerated emission reductions with the addition of CCS on NGCC plants. As natural gas with carbon capture can use postcombustion capture (PCC) technology, the lessons from current operating CCS facilities such as BD3 can contribute to their success.

Corwyn Bruce, P.Eng. is the vice president, project development & advisory services at the International CCS Knowledge Centre.

The original article can be found on page 40 of the American Coal magazine (Issue 1, 2020) ?— the official publication of the American Coal Council.

Please note: The content and external links within this article do not constitute an endorsement or an approval by the International CCS Knowledge Centre (Knowledge Centre) of any products, services, or opinions of the authoring corporation, organization, or individual. The Knowledge Centre bears no responsibility for the accuracy, legality, or content of the external site or for that of subsequent links.