With a room full of technical experts from around the world, many of whom are in demonstration mode with carbon capture and storage (CCS) projects, the recent IEAGHG’s Post Combustion Capture Conference (PCCC), held in Tokyo (September 17-19, 2019) provided an opportunity to present technical updates on SaskPower’s Boundary Dam Unit 3 Carbon Capture Facility (BD3), and to consider net-zero opportunities for CCS.

A biannual conference, PCCC provides a valuable forum to discuss the various issues related to post-combustion capture technologies, acting as a platform for technology providers and developers to share their experiences and knowledge. Mandated to share the learnings gained from operating the BD3 (startup through optimization), the International CCS Knowledge Centre was represented by Corwyn Bruce, Vice President, Technical Services and Senior Engineer, Yuewu Feng who made four presentations at the conference.

Presentation #1: Performance Enhancing Benefits of Applying Redundancy and On-line Serviceability to Key Equipment at SaskPower’s BD3 Capture Plant (Abstract)

And

Presentation # 2: Reliability Improvements of SaskPower’s BD3 Capture Facility Through Operational and Process Design Changes- Experiencing the First Four Years of Operations (Abstract)

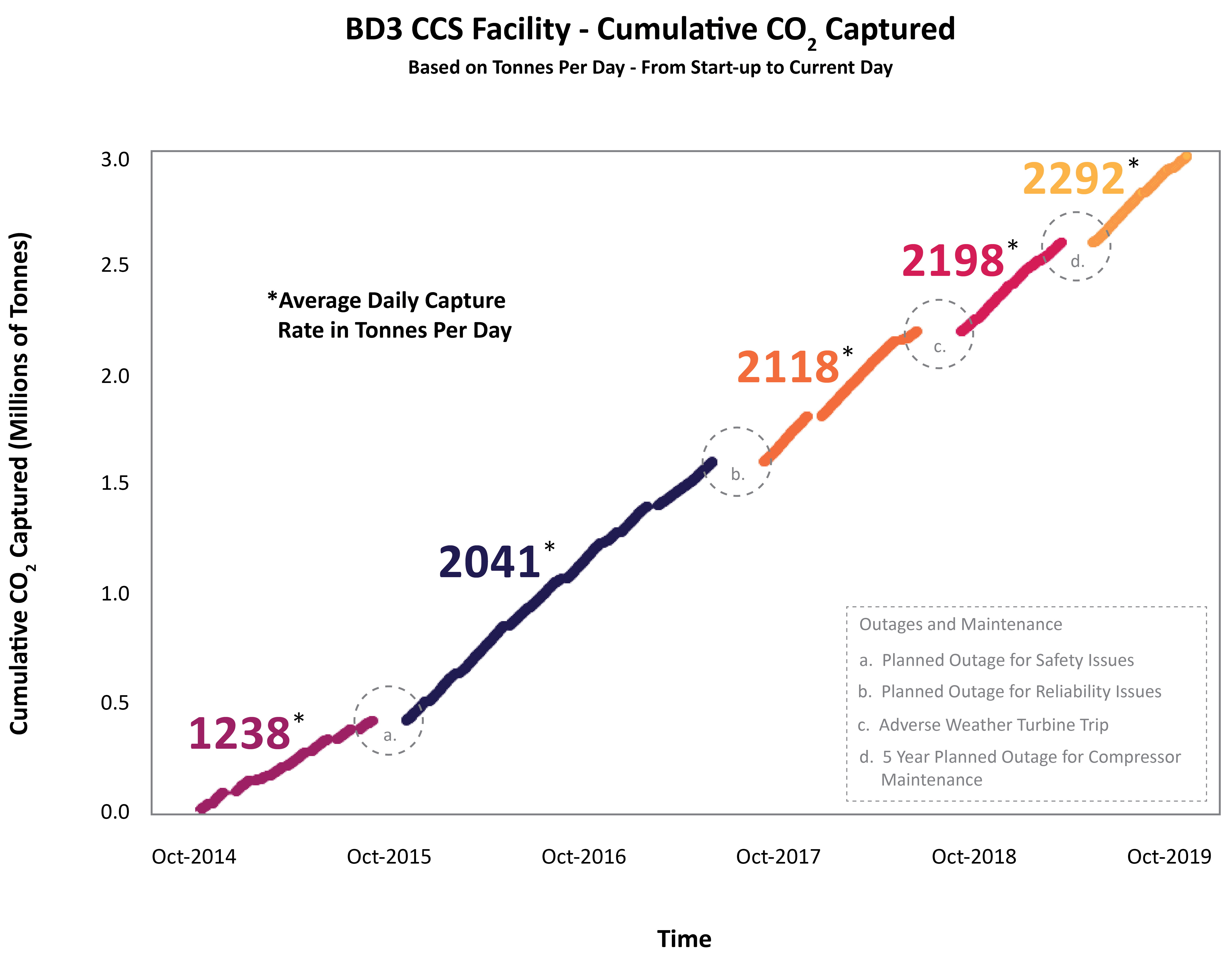

The first two presentations focused on the various corrections that were made to BD3. Now five years since it began operations, BD3 is on the eve of reaching three million tonnes of CO2 captured and safely and permanently stored through either enhanced oil recovery or deep geological storage. BD3’s large-scale carbon capture retrofit has yielded both operational and design changes that can be applied to future installations of industrial scale CCS facilities. Benefits of these changes include decreased operating and maintenance costs and improved performance and reliability.

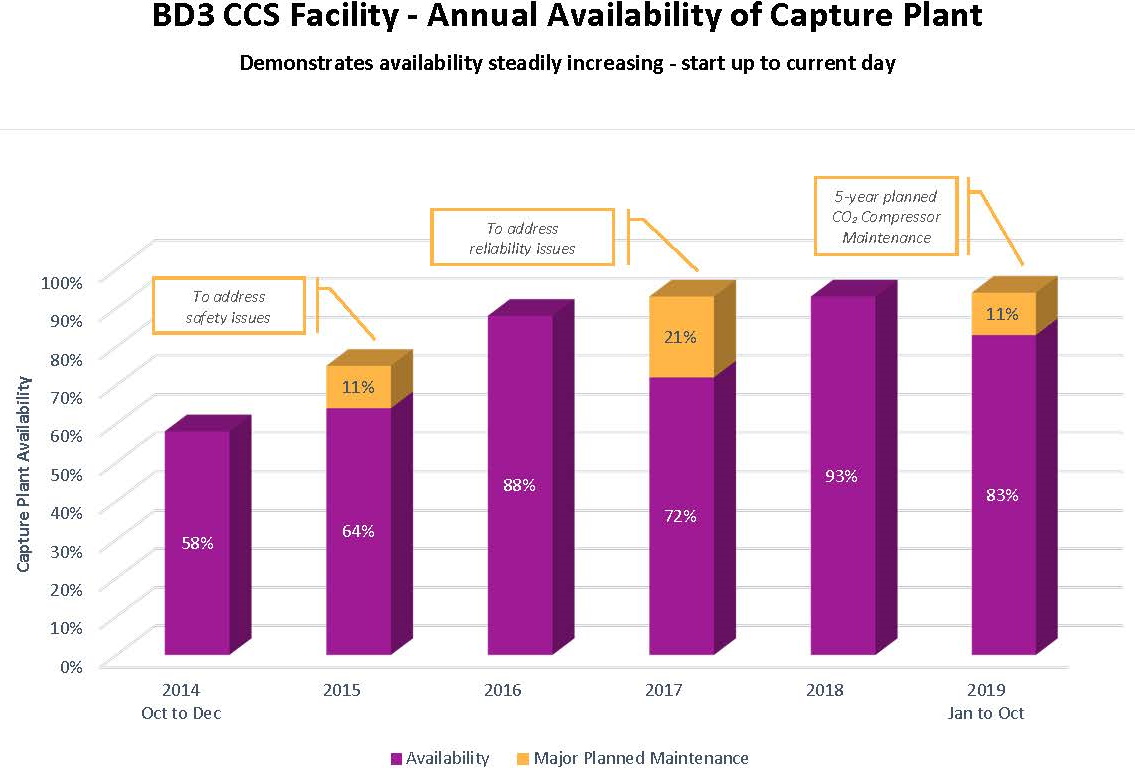

Figure 1 illustrates the performance results of applying various technical changes over its current operational timeline, leading to an ability to steadily improve the availability of the capture facility (click here for the abstract). The correction of difficulties associated with the lean rich heat exchangers, along with other changes to address deficiencies in the plant, improved the performance and reliability of the capture facility. The presentations also included performance trends from the capture facility that highlighted how each change contributed to performance improvements. A key lesson came through performance data evaluation – it indicated that redundancy and on-line serviceability should be considered for design standards in future amine-based post combustion CO2 capture facilities (click here for the abstract).

Presentation #3: Derate Analysis for SaskPower’s Boundary Dam Unit 3 During the First Four Years of Operation(Abstract)

In the third presentation it was explained how further advancements have made it possible for BD3 to increase its ability to operate closer to theoretical maximum capture rate as shown in figure 2.

Interestingly though, there is a disconnect between the installed capacity (design capacity) and achieved capacity of the capture plant. The disconnect is partly due to the limited economic incentives that exist to capture more CO2 than what is needed. By examining the facility’s operational history, a diagnosis can be made on the main cause of capture losses-derates and outages. Which in turn, helps evaluate and determine mitigation measures. The presentation also highlighted how changes to the capture facility has significantly reduced the instances of outages of the capture plant (click here for the abstract).

Increasing reliability of existing carbon capture facilities is important for optimization and key to driving the global deployment of CCS. Although BD3 is demonstrated on an industrial scale, learnings and refinements could be accelerated with the deployment of multiple generations of CCS over a period of time.

Presentation #4: Approaching Negative Greenhouse Gas Emissions Via Bioenergy With CO2 Capture And Storage In Saskatchewan (Abstract)

The fourth presentation by the International CCS Knowledge Centre offered at PCCC5 focused on a high-level cost analysis of converting the Shand Coal-Fired Power Station (Shand) to Bioenergy with CO2 Capture and Storage (BECCS). The Intergovernmental Panel on Climate Change (IPCC) reported that the world will need to take dramatic steps to avoid increasing the earth’s temperatures more than 1.5 ?C above pre-industrial levels.

The IPCC report includes an assessment of the role of CO2 removal from air technologies and negative emissions technologies (NETs) such as BECCS. BECCS removes atmospheric CO2 through the combustion of the biomass to produce energy while simultaneously capturing the produced CO2. The cost analysis utilizes the finding from the Shand CCS Feasibility Study and the Phase IV Biomass Co-Firing Report from the Canadian Clean Power Coalition to explore the potential advantages which may be realized with a biomass co-firing unit equipped with a 95% CO2 capture capacity facility (click here for the abstract).

Sharing knowledge gained from the real-life experiences of BD3 as well as information from the Shand CCS Feasibility Study with high-level considerations for BECCS, provided great value to the PCCC community. It was observed that through questions and active engagement, there was a clear depth of understanding of the technology by the attendees. This showed a level of maturity that is promising for the next generation of large-scale CCS deployment. Collectively we are ready. What is needed now is the practice of implementation.