Managing resources and taking care of the planet while allowing societies to prosper is a topic seen on news feeds every day in the form of emission reduction conversations. Industry is responsible for 40% of global energy demands and is central to economic development around the world. The downside is that industrial processes account for one-quarter of carbon dioxide (CO2) emissions.

Prospering societies are demanding and there is little evidence that those that “have” want less. Many are inclined to want more, and the faster the better. This is a fact of the world we live in. Consider this. On May 30, 2019 FedEx announced they would be delivering 7-days-a-week to U.S. residents. Stating on Twitter, “FedEx Ground will deliver to residences every day of the week beginning in January 2020, because shoppers don’t run on business days – they run every day.” Ryan Kelly, VP – Global eCommerce Marketing at FedEx further posted on LinkedIn that, “FedEx proprietary research found that 50% of online shoppers and 70% of merchants would definitely or probably use Sunday delivery service – especially for more expensive, urgent purchases.” (First Flight Solutions)

Amazon is already providing 7-day-a-week service in many markets. UPS is adding 20 automated facilities to its network by the end of 2019, with the ability to sort an additional 400,000 packages per hour. The company has seen next-day air package volume increase in the second quarter of 2019 by 30.3% from the same period in 2018. (Business Insider)

Transforming Industry Through CCS

What does all of this have to do with Carbon Capture Storage (CCS/CCUS)? Trace this activity back to the source and it all begins with energy, cement and steel. In other words, industry. It takes industry to create infrastructure to build buildings, warehouses, roads, cars, planes and support businesses.

According to the IEA Report: Transforming Industry through CCUS, demand for cement, steel and chemicals will remain strong to support a growing and increasingly urbanized global population.

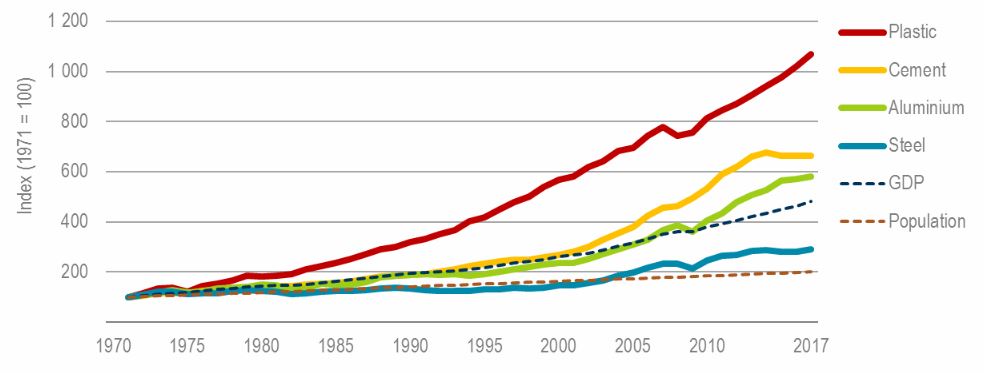

Figure 1: Global trends in the production of major industrial products, GDP and population over the previous four decades

Demand for industrial products is closely linked with GDP growth.

_______________________________________________________________

Global population expansion, increased urbanization, and economic and social development will underpin continued strong demand for these key materials. Advanced economies currently use up to 20 times more plastic and 10 times more fertiliser per capita than developing economies (IEA, 2018a), and global demand for cement is expected to increase 12-23% by 2050 (IEA, 2018b).

Stewardship and Demand

So how do we fuel the demand for more and provide proper stewardship of the required resources? With industry as the source of almost 25% of CO2 emissions, cleaning it up it must be part of the clean energy transition – to address the decarbonization challenge while supporting sustainable and competitive industries. The answer is with the inclusion of CCS.

CCS is expected to play a critical role in decarbonizing industry as it has been proven to be one of the most cost-effective solutions available for large-scale emissions reduction. In the IEA Report, a pathway is set out that aligns with the ambitions of the Paris Agreement, drawing on CCS to reduce global industry emissions by one-fifth. Within this pathway, more than 28 gigatonnes of carbon dioxide (GtCO2) is captured from industrial processes in the period to 2060, the majority of it from the cement, steel and chemical subsectors.

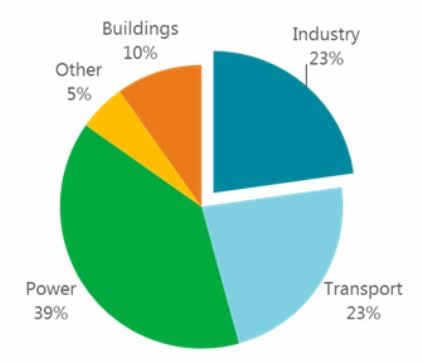

Industry is the second-largest source of CO2 emissions from energy and industrial processes (equal with transport) after the power sector. It accounted for nearly 40% of total final energy consumption and nearly one-quarter (8 GtCO2) of direct CO2 emissions in 2017. If indirect emissions (i.e. emissions resulting from industrial power and heat demand) are also taken into account, the sector is responsible for nearly 40% of CO2 emissions.

Figure 2: Direct CO2 emissions by sector, 2017

Steel and cement are the two highest-emitting industry subsectors. Together they accounted for 12% of total direct global CO2 emissions in 2017.

If the cement industry were a country, it would be the third largest emitter in the world. In 2015, it generated close to 2.8 billion tonnes of CO2, equivalent to 8% of the global total – a greater share than any country other than China or the US. (Carbon Brief).

Industry emissions are particularly hard to abate in the energy system because many of the processes require high temperature heat, accounting for approximately one-third of the industry sectors final energy consumption. Approximately half of the emissions from cement are process emissions. This is a principle reason that cement emissions are often considered difficult to cut: since this CO2 is released by a chemical reaction, it cannot be eliminated by changing fuel or increasing efficiency.

A further 40% of cement emissions come from burning fossil fuels to heat kilns to the high temperatures needed for the process to be successful. The last 10% of emissions come from fuels needed to mine and transport the raw materials.

Bill Gates, American business magnate, investor, author, philanthropist and humanitarian points out in his article, Here’s a Question You Should Ask About Every Climate Change Plan, “ There are reasons to be optimistic. Carbon capture is deemed an innovative approach to reducing emissions from cement, before the carbon can do any damage.” Further he says, “Carbon capture is probably the approach we will have to take with cement.”

CCS Cuts Cost and Complexity

The International CCS Knowledge Centre has demonstrated with the Shand CCS Feasibility Study that carbon capture technology on a full-chain, coal-fired power plant with 2nd generation technology, could have a capture rate over 90% with a 67% reduction in the cost per tonne of CO2 captured. The physics and economics that govern the design and operation of thermal power plants is remarkably similar throughout the world. In fact, many of the findings from the SaskPower’s Boundary Dam 3 CCS Facility can be further applied to other post combustion capture on industrial processes.

Post combustion CCS takes flue gases (the emissions) and cleans them up using a solvent (called amine) downstream from the emission source (i.e. post combustion). So building a CCS facility to clean up emissions before they are emitted means current assets like cement plants can be retrofitted.

With CCS technology, the sector can avoid costly and complex industry sector transformation.

Back to the IEA Report, it points out many other benefits associated with the deployment of CCS technology. For instance, the report cites that the development of CCS hubs could support new investment opportunities by investing in shared CO2 transport and storage infrastructure, it could reduce unit costs through economies of scale as well as enable – and attract – investment of CO2 capture for existing and new industrial facilities.

Furthermore, establishing markets for premium lower-carbon materials could minimize competitiveness impacts. Public and private procurement for lower-carbon cement, steel and chemicals could accelerate the adoption of CCS and other lower-carbon processes, and the large size of these potential contracts for these materials could help establish significant and sustainable markets worldwide.

It is clear that there is no curbing demand. Energy, cement and steel are essential industries that drive economic growth and development and are the backbone of prospering societies. The future production of these materials must be more efficient and must emit less CO2 if climate goals are to be met. CCS technology is a concrete solution to reducing industrial emissions, allowing us to support industries while continuing to enable societies to evolve and prosper.