With the oil and gas sector contributing 9% of global greenhouse gas (GHG) emissionsi, there are opportunities for the sector to promote clean energy and sustain innovation as it leverages opportunities for transition to a low carbon energy. The recent Intergovernmental Panel on Climate Change (IPCC) report details the continued impact of global warming attributable to humanii and the need for interventions from all fronts. Global attention is focused on high industry emitters such as the iron and steel plants, cement plants, oil refineries, as well as others with high purity carbon dioxide (CO2) emissions. This has prompted many in the oil and gas industry to embrace the prospects of innovative technology, specifically, large-scale carbon capture, utilization, and storage (CCUS/CCS) as an option to support the Paris Agreement targets to limit global warming by 1.5°C and to reach net-zero global emissions by 2050.

With 40 million tonnes (Mt) of CO2 currently being captured at large?scale facilities, approximately three?quarters is from oil and gas operationsiii, demonstrating that this sector is active in developing and deploying CCS. Therefore, the industry could serve as ‘lead actors’ on the road to net zero. Like lead actors perform a respected role in a theatrical production, the oil and gas sector could also play a significant role in ensuring broad use of large-scale CCS for emissions reductions.

CCS– Gaining increased recognition

As large-scale CCS continues to gain attention by decision-makers in government and business leaders in many countries, there seems to be a greater focus of fast-tracking expectation of reaching the 2050 target across sectors. Currently, there are 26 commercial CCS facilitiesiv operating around the world (plus an additional 39 in various stages of development) with an operational capacity to capture and permanently store 40 Mt of CO2 every year. In their recent report titled ‘Climate Change 2021: The Physical Science Basis’, the IPCC stressed the importance of CCS, when it said, “Carbon capture and storage, which alone does not remove carbon dioxide (CO2) from the atmosphere, can help reduce atmospheric CO2 from industrial and energy-related sources…”v As interest is CCS technology grows around the world, it is important to note that proper provision should be made for attendant policies and incentives to support the deployment and increase uptake of the technology.

There is a great opportunity for improvements in carbon capture technology as well as a reduction in risk through iteration for CCS deployment. An example is seen in the much-anticipated Lehigh Edmonton CCS Feasibility Study – which looks at the adaptation of commercial-scale CCS plants on cement operations. This report applies learnings from the publication, 2nd Generation CCS Shand Study as well as the lessons from the operating Boundary Dam 3 CCS Facility. With the rapidly expanding knowledge base of carbon capture, the application of large-scale CCS can be further translated within the industrial and oil and gas sectors.

CCS with the Oil and Gas Sectors

According to the US Department of Energy, “CCUS technologies can capture at least 95% of CO2 emissions generated from natural gas power… (and this will) dramatically reduce carbon pollution in our fight against climate change.”vi This positions the oil and gas sectors to be lead actors in emission reductions through carbon capture technology.

There are a several important examples where the value-chain for oil and gas has achieved successful CCS initiatives. Shell’s Quest CCS facility is an excellent example – where it has captured and permanently stored 1 Mt of CO2 every year since its inception in 2015.vii Several other refineries around the world are successfully using their CCS facility for enhanced oil recovery CO2-EOR and setting goals to reach net-zero in their sector. Shute Creek Gas processing facility in Wyoming, USA has been separating and transporting CO2 via ExxonMobil, Chevron, and Anadarko Petroleum pipeline systems since 1986.viii ADNOC, at its Al Reyadah facility in the United Arabs Emirates, has a capturing capacity of 800,000 tonnes of CO2.ix In Saskatchewan, CO2 storage in the Weyburn-Midale reservoirs has permanently sequestered over 36Mt of CO2 underground.x

According to the Clean Air Task Force, oil production with the use of CO2-EOR results in 30% less greenhouse gas emissions than traditional extraction and results in a 37% reduction in CO2 emissions per barrel.xi This is a significant contribution to the reduction of carbon emissions and helping the 2050 targets become more of a reality.

“CCUS contributes to emissions reductions in all regions in the Sustainable Development Scenario…. (and) demand for CO2 for EOR is a key driver in the near term, alongside measures to decarbonise the refining and petrochemical sectors.” – IEAxii

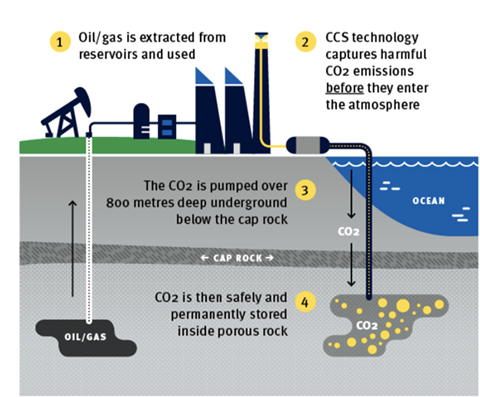

The illustration shows CCS process end to end operations in the oil and gas sector where the capture CO2 is sent deep underground for use in enhanced oil recovery (EOR) – where the CO2 is recycled and eventually permanently stored safely in depleted oil/gas formations.

Ease of CO2 Capture in Oil and Gas

The process to capture CO2 involves extracting it from other gaseous substances and preventing large quantities of CO2 from being released into the atmosphere. CO2 can be captured from natural gas, membrane gas separation, or flue gases at large CO2 point sources. This is done using either pre-combustion, post-combustion or oxyfuel combustion.

Carbon capture in refineries has some competitive advantages over the technology used in coal plants, cement plants, and iron and steel plants. The primary advantage is that capturing CO2 emissions at refineries is less complex – with a reduction in the use of steam requirement for CO2 capture and compression, less cumbersome technological processes of capturing CO2, and lower cost of operating.

CCS Hubs – Taking advantage

With the increase in intent to build large-scale CCS facilities across a few countries, there is a need for industries in the cluster network of CCS facilities to maximize available benefits. This could be through the creation of CCS hubs that allow for neighbouring industries to share infrastructure, reduce cost, and minimize potential project risks, owing from proximity to one another. CCS hubs would also enable industries in a cluster network to gain economies of scale, thus leading to proportionate savings in costs, minimizing waste, and help in the continuous reduction of emissions among high industry emitters.

Globally, there are a few examples of CCS hubs in operation where refineries are part of the industry cluster. An example of this is the Alberta Carbon Trunk Line (ACTL) in Alberta, Canada. “The ACTL system currently captures CO2 from two anchor projects – a refinery and a fertilizer facility (Sturgeon Refinery owned by Northwest Redwater Partnership (NWR) and Nutrien’s Redwater Fertilizer Facility).” xiii

The United Kingdom (UK) through the Northern Endurance Partnership (NEP) is also looking to provide common infrastructure to decarbonize its industries towards achieving its target of net zero emissions by 2050. This initiative will secure offshore storage in the North Sea (in a geological formation known as Endurance) by setting up an east coast cluster at UK’s industrial heartland of Teesside and Humber. The cluster will be responsible for nearly half of CO2 emissions from this UK industrial clusters and will help to deliver the CCS infrastructure needed to decarbonize this key industrial hub of the UK. The Endurance storage site will have the capacity to store 450M tonnes of CO2 and with other potential stores nearby could take the storage capacity to around 1B tonnes.xiv

In China the Xinjiang Junggar Basin CCS hub is another and Norway has the Northern Light, which is a Joint Venture amongst Equinor, Shell and Total. Other CCS hubs are being constructed, such as the Cork industry cluster in Ireland, which has Irving Oil’s Whitegate refinery, the Bord Gais Energy gas-fired power plant and the Aghada combined cycle power station.

Refineries that are within CCS hubs are well positioned to move forward in their operationalization, to advance goals of reductions in emissions. Other high industry emitters should also take advantage of available CCS hubs in their cluster network, as this would help minimize their cost, reduce risks, and improve emissions reduction from their facilities.

Oil and gas as lead actors for emissions reduction

Industries in the oil and gas sector are well-positioned to accelerate the pace of development and deployment of CCS technologies and to gain a commercial edge over other sectors. The deployment of CCS has the potential to continue to increase significantly across the globe, contributing to the decarbonization goals and promoting clean energy.

CCS in the oil and gas industry is a win-win scenario. On the environmental side, it contributes to setting goals to achieve net-zero target by 2050 both from a capture and a permanent storage perspective and on the business side, it helps reduce cost and increase production in the case of CO2– EOR. This would also help to reduce CO2 emissions, lower carbon footprint in production, and provides numerous opportunities in energy transition.

As more refineries around the world take up the use of large-scale CCS there will be a greater contribution to the global emissions target, and this continues to make the oil and gas sector play the role of “lead actors” in getting the world to net-zero.

References

iMcKinsey “The Future is now: How oil and gas companies can decarbonize” (2020) https://www.mckinsey.com/industries/oil-and-gas/our-insights/the-future-is-now-how-oil-and-gas-companies-can-decarbonize

iiIPCC. “Summary for Policymakers. In: Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change” (2021) https://www.ipcc.ch/report/ar6/wg1/downloads/report/IPCC_AR6_WGI_Full_Report.pdf

iiiIEA (2021), Net Zero by 2050, IEA, Paris https://www.iea.org/reports/net-zero-by-2050

ivGlobal CCUS Institute “Global Status of CCS 2020”.(2020) https://www.globalCCUSinstitute.com/wp-content/uploads/2020/12/Global-Status-of-CCUS-Report-2020_FINAL_December11.pdf

vIPCC. “Summary for Policymakers. In: Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change” (2021) https://www.ipcc.ch/report/ar6/wg1/downloads/report/IPCC_AR6_WGI_Full_Report.pdf

viU.S. Department of Energy “Point-Source Carbon Capture Can Filter At Least 95% of Emissions from Natural Gas and Industrial Operations” DOE Invests $45 Million to Decarbonize the Natural Gas Power and Industrial Sectors Using Carbon Capture and Storage | Department of Energy

viiShell Canada “Quest CCS Facility Captures and Stores Five Million Tonnes of CO2 Ahead of Fifth Anniversary” (2020)

viiiNovak Mavar, K.; Gaurina-Me?imurec, N.; Hrn?evi?, L. “Significance of Enhanced Oil Recovery in Carbon Dioxide Emission Reduction.” (2021) https://doi.org/10.3390/su13041800

ixAbu Dhabi National Oil Company “ADNOC to Build on its Position as one of the Least Carbon-Intensive Oil and Gas Producers in the World” (2020) https://adnoc.ae/en/news-and-media/press-releases/2020/adnoc-to-build-on-its-position-as-one-of-the-least-carbon-intensive-oil-and-gas-producers

xSaskPower “Weyburn-Midale C02 Storage and Monitoring Project (2021) https://www.saskpower.com/Our-Power-Future/Infrastructure-Projects/Carbon-Capture-and-Storage/Carbon-Storage-Research-Centre

xihttps://www.catf.us/wp-content/uploads/2019/06/CATF_EOR_LCA_Factsheet_2019.pdf#:%7E:text=CO%E2%82%82%252

xiiIEA (2020), CCS in Clean Energy Transitions, IEA, Paris https://www.iea.org/reports/ccus-in-clean-energy-transitions

xiiiInternational CCS Knowledge Centre “Importance of CCS Hubs.” (2020) Importance of CCS Hubs « (ccsknowledge.com)

xivNet Zero Teesside “The Northern Endurance Partnership enabling Net Zero Teesside and the East Coast Cluster” (2021) https://www.netzeroteesside.co.uk/northern-endurance-partnership/